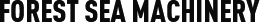

The GZG series vibrating feeder is a universal vibrating motor-driven feeding equipment developed and produced by our company. Widely used in mining, metallurgy, coal, glass, building materials, light industry, chemical industry, power, grain and other industries, it is used to continuously and uniformly feed block, granular and powdery materials from storage warehouses or funnels to the receiving device.

Product features and scope of use

1. Simple structure, large processing capacity, simple structure, relatively easy installation and maintenance.

2. Stable vibration, reliable operation, long service life, etc

3. There are two installation methods: hanging and seated.

4. The vibration source of the heavy-duty vibrating feeder can be equipped with an exciter form.

5. Can be lined with wear-resistant lining plates such as manganese steel and ceramics

5. The material conveying distance can be extended according to customer needs.

Main technical parameters

Type | Processing capacity (t/h) | Maximum granularity (mm) | Amplitude (mm) | Electric motor | ||

Horizontal | Tilted | Rotation speed (rpm) | Power (kw) | |||

GZG40-90 | 40 | 45 | 80 | 3-5 | 1500 | 2×0.25 |

GZG50-100 | 55 | 56 | 100 | 2×0.4 | ||

GZG60-120 | 75 | 90 | 120 | 2×0.4 | ||

GZG70-140 | 100 | 115 | 150 | 4-6 | 1000 | 2×0.55 |

GZG80-140 | 130 | 150 | 150 | 2×0.55 | ||

GZG90-150 | 170 | 200 | 240 | 2×0.75 | ||

GZG100-160 | 260 | 300 | 260 | 2×1.1 | ||

GZG120-160 | 330 | 380 | 300 | 2×1.5 | ||

GZG150-180 | 560 | 620 | 300 | 2×2.2 | ||

GZG180-180 | 700 | 850 | 350 | 2×3 | ||

GZG200-200 | 1000 | 1200 | 350 | 2×3.7 | ||