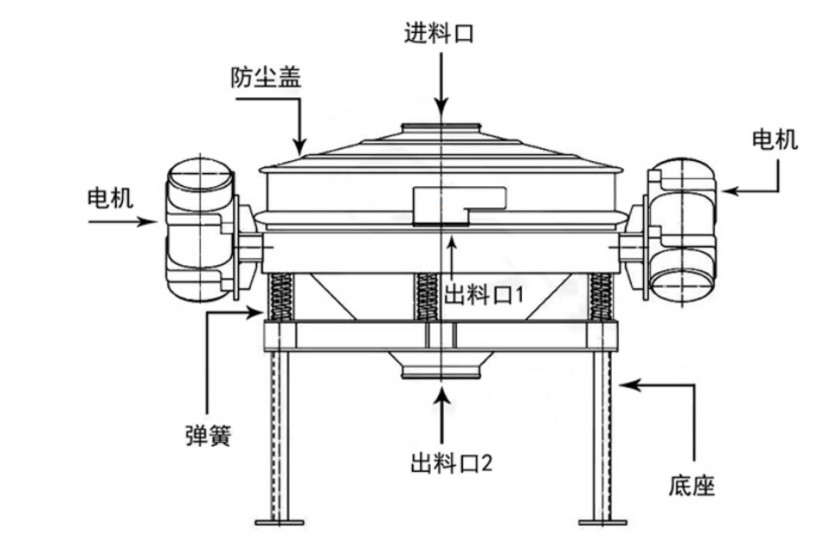

The straight-through screen (also known as a straight-discharge vibrating screen) uses a single or double vibrating motor as the excitation source. The vibrating motor is located on the side of the machine, and the material enters the equipment interior and performs an elliptical movement trajectory under the action of the excitation source on the screen surface. The material quickly and repeatedly completes the screening action, and the vibrational energy continuously dissociates, disperses, and reassembles the material, allowing it to quickly pass through the mesh. Material that cannot pass through the mesh is discharged from the screen by the machine's movement trajectory through the upper outlet, completing the screening process.

Product features and scope of use:

1, high screening efficiency, high screening accuracy, easy to maintain and clean, simple operation, etc.

2.Complete a large number of screening operations in a relatively short time, and have high screening efficiency.

3.easy to maintain and clean, will not produce the problem of dust flying, easy to operate, easy to master.

4. In addition to large miscellaneous output, the direct type vibration sieve outlet is designed at the bottom of the sieve, and the finished product can quickly cross the mesh, reduce the residence time of materials in the screening surface, and greatly increase the screening output.

Main technical parameters

Type | Diameter(mm) | Screen area (m²) | Layers | Power Kw | Dimensions (mm) |

ZPS-600 | 580 | 0.26 | 1-2 | 0.18 | 1000*600*550 |

ZPS-800 | 780 | 0.48 | 0.25 | 1100*800*600 | |

ZPS-1000 | 960 | 0.72 | 0.25 | 1280*100*700 | |

ZPS-1200 | 1160 | 1.05 | 0.55 | 1550*1200*750 | |

ZPS-1500 | 1460 | 1.67 | 1.5 | 1850*1500*900 |